Synopsis: In this tool test, we put twelve 1/2-in. and 3/4-in. bits to the text, drilling through framing lumber and PT 4x4s, as well as intentionally striking a nail to see how the bit reacts to the damage and performs afterward. Some standout bits leave particularly clean holes or chew through nails with ease, and we identify a best value bit as well as a best overall performer.

F or nearly everyone who works in residential construction, wood-boring bits are the preferred way to make medium-sized holes. They’re easy to find in stores, they’re not too expensive, and they generally last a long time even with almost everyday use. During framing, wood-boring bits are used to drill sill plates for anchor bolts, and sometimes to recess their washers and nuts. You’ll see them used during the mechanical rough-in phase when they’re used for most of the drilling through framing for electrical wires and small-diameter pipes. Toward the finish stage, wood-boring bits are used for things like drilling cabinets for pipes and wires, and for drilling mounting blocks and siding for exterior lights and outdoor receptacles. Wood Boring Drill Bit

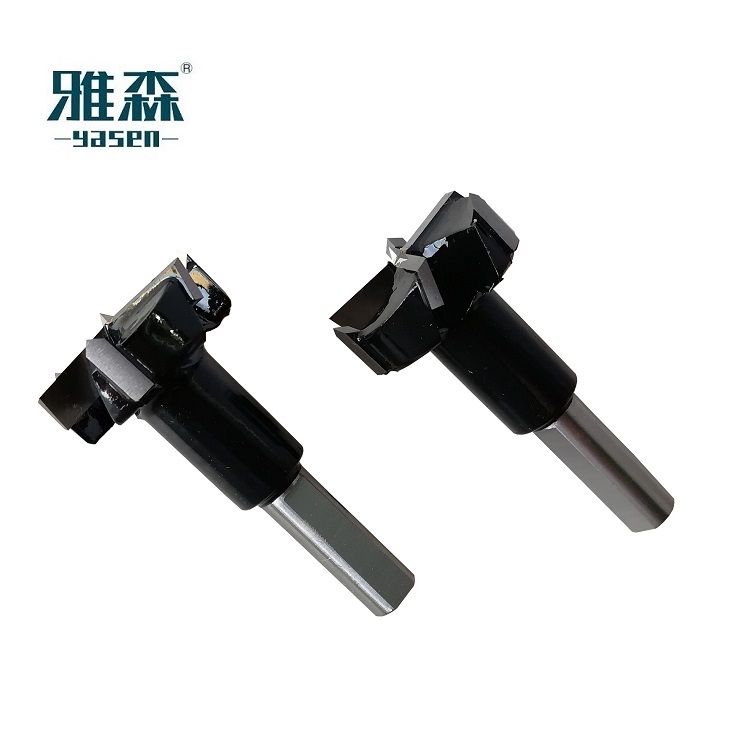

The wood-boring bits in this test are meant for fast drilling, and as a consequence, many leave a ragged, splintery hole. If you’re looking for a nice, clean hole presentable for finished work, you’ll probably want to use a Forstner bit. On the occasion that you need to drill a hole for larger pipes or ductwork, you’ll need to use a hole saw, because wood-boring bits like the ones I tested max out at around 1-1⁄4 in. to 1-1⁄2 in. in diameter.

To test the bits, I laid all the material flat on sawhorses at standard working height. After drilling all the 1⁄2-in. and 3⁄4-in. holes of the same bit brand and type, I installed a fresh battery on the drill to judge the next pair of bits. The test process was as follows:

1. Drill eight holes in 2×6 framing lumber. This simulates drilling into a stud, joist, or plate.

2. Drill three holes in a pressure-treated 4×4. This simulates drilling into a deck post, perhaps for hardware such as a carriage bolt.

3. Intentionally nail-strike a 3-in. framing nail embedded in the 2×4. This simulates an unintentional nail strike while drilling near a connecting point in framing material.

4. Return to the original 2×6 and drill two holes. This judges how the newly damaged drill bit performs in the original work.

Wood-boring bits can be grouped into two main categories: spade and auger. Historically, spade and auger bits were considered commodity-type consumables. Modern versions are notably more complex in shape, and sometimes combine aspects of both spade- and auger-bit geometry. The manufacturers claim that the hybrid shapes are “fastest” or “cleanest,” or that they make drilling “effortless,” which is not always the case. Hybrid features include auger tips, sharpened curved flutes, coated flutes, and curved paddles.

Sometimes called paddle bits, spade bits are the least expensive of the group. These bits have a pointed or auger tip, followed by sharp, pronounced shoulders that do the cutting. Spade bits are widely available at nearly all box stores, hardware stores, and lumberyards. They can be purchased individually or in larger sets, ranging in size from 1⁄4 in. to 1-1⁄2 in., often in 1⁄16-in. increments. All of these bits are impact-ready and have a 1⁄4-in. hex shaft. Standard spade bits are usually 6 in. long, but you can get stubby versions that are 4 in. and “installer” versions commonly available in 12-in. and 16-in. lengths.

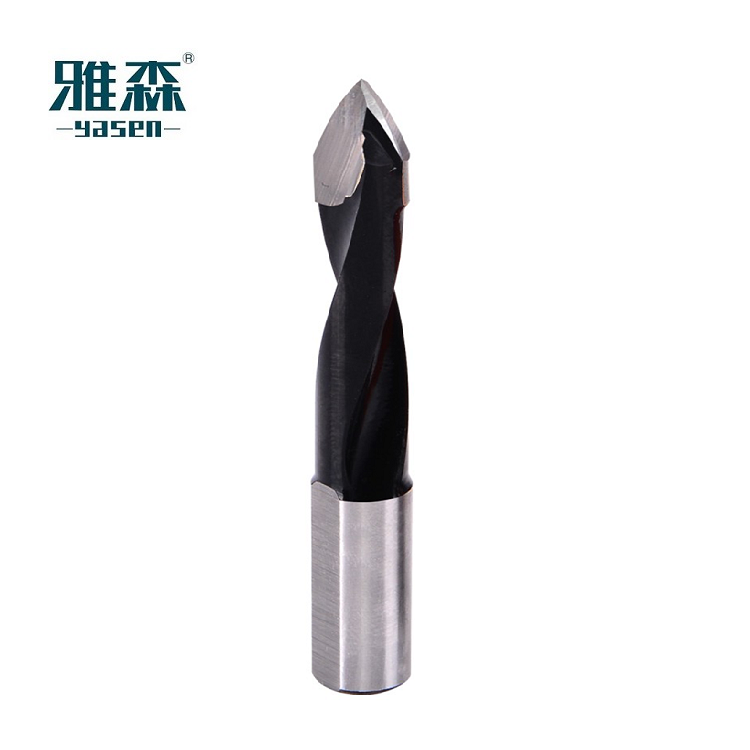

In comparison, auger bits generally look like traditional twist bits, but larger in diameter. The flutes that wind in a spiral make these bits better at chip extraction. Auger bits, sometimes called “ship augers,” usually have two flutes along the shaft of the bit, but sometimes one or three flutes. Auger bits are available in sizes similar to spade bits and have several sizes of shafts for securing in a drill chuck. These bits are also more expensive than spade bits. Manufacturers don’t always use the word “auger” to describe these bits. Instead, popular brands use terms such as self-feeding bits, power bits, tri-flute bits, or utility bits.

For testing the bits, we chose the two most commonly used bit sizes: 1⁄2 in. and 3⁄4 in. Half-inch holes are common for running nonmetallic electric cable, while 3⁄4-in. holes are frequently used for running 1⁄2-in. PEX and copper tubing for domestic water lines. I used an 18v cordless drill with a keyless chuck for testing, because that’s what I see plumbers and electricians using for drilling holes this size. Right-angle and other large drills are generally reserved for holes 1-1⁄2 in. and up.

All testing with the drill/driver was done on the “low” setting. This translates to higher torque, but lower rpm. This levels the playing field, as some bits are not meant to spin faster than 600 rpm, and the highest possible rpm on the “low” setting is 400. A standard 1⁄2-in. keyless chuck in a cordless drill allowed me to use of all of the bits, as some bits have larger shanks than others. A 1⁄4-in. hex head on an impact driver couldn’t accommodate some of the larger bits.

I drilled holes in 2×6 SPF framing lumber, 4×4 pressure-treated post material, and nail-embedded 2×4 SPF framing lumber. I judged the speed of drilling, the effort required, and hole cleanliness. I also intentionally ran the bits into nails and judged their performance afterward.

The Spyder Stingers are great bits. They closely resemble a traditional spade bit, with the exception of a full-threaded auger tip. The Stingers pulled through the work better than any of the other bits while leaving clean, smooth-sided holes. I recommend these bits.

The Diablo SpeeDemons are an exceptional value and perform very well in fastener-free wood. These bits closely resemble the Hilti and Bosch bits, and like those bits, couldn’t strike through the embedded nail with the 3⁄4-in. bit. After hitting a nail, the bit was sufficiently dulled enough that it had difficulty drilling in clean wood.

The Bosch spade bit has features such as a full-threaded tip, pointed cutting shoulders, and a curved design that the manufacturer calls a SpeedWave Paddle. Unfortunately, these features didn’t seem to translate into any notably improved performance when drilling. And as a negative, the 3⁄4-in. bit was unable to strike through the embedded nail.

I was only able to test the 3⁄4-in. size in the Bosch auger bit, as I was unable to find a 1⁄2-in. bit. The bit pulled slowly in most of the lumber, but absolutely chewed through the embedded nail with ease. I highly recommend this bit if you know you’re going to be drilling in or around any embedded metal.

Consider these the most plain-Jane spade bits with the most traditional shape of the entire spade bit group. These no-frills bits are easy to find, cut very cleanly, and have an attractive price. If I broke or ruined one of these DeWalt bits I wouldn’t feel bad, and they work well enough that I would probably buy two at a time to make sure I had a spare.

Diablo advertises that these bits are for nail-embedded wood. While they did drill well, they come with a steeper price than the Bosch Daredevil. For the price, I would expect bits that perform better than the rest of the group.

Hilti has a reputation as a premium brand that does most things well. As such, I was surprised to see that their spade bits were not made in Germany like many of their other tools. In fact, their spade bits look exactly like the Bosch and Diablo bits. Considering that their premium price did not yield premium performance, I would choose something else.

The Irwin Speedbor Supreme augers have a simple, single-flute design. As the most expensive bits of the group, I had high hopes for them that were dashed in practice. They pulled well through the PT lumber, but couldn’t get through the nail-embedded wood. They also left messy exit holes.

The appearance of the Irwin Tri-Flute bits is striking, but the 1⁄2-in. bit couldn’t strike through the nail, and both the 1⁄2-in.- and 3⁄4-in.-bit tips clogged while trying to drill through PT lumber. I also struggled to pull the 3⁄4-in. bit back through the wood. The saving grace of these bits is that they leave clean holes including smooth entry and exit faces.

I was excited about testing these Milwaukee bits, but I found their performance subpar. They have tapered flutes, which I assumed would allow the bit to drill more easily compared to a bit with a consistent diameter. Unfortunately, the 1⁄2-in. bit immediately clogged with wood, and was unable to drill even two holes in the 2×6. The 3⁄4-in. bit was also disappointing.

The Stinger auger bits pulled really nicely through all of the test wood. The flutes were sharp, but maybe too sharp, as I couldn’t actually tell when I was through the back side of the piece because the flutes were still digging into the sides of the holes. Despite this little quirk, the bits did a good job.

The first thing I noticed about these bits is how fast they drill—the fastest of the bunch I tested. But despite the speed, they didn’t leave clean holes, and the tearout on the exit side of the holes was excessive. Running the drill in reverse to retract the bit left a clogged hole; running the drill forward while retracting was a bit better.

Of the spade bits, there was no clear standout that performed better than others. Nearly all of the spade bits achieved the same results in the same manner. The Spyder Stinger spade bits pulled notably well through the testing material, but still only marginally better than the rest of the group. For boring holes in wood, spade bits will suit the majority of your needs just fine, especially given their availability and price point. They have no problem drilling through pressure-treated 4x material and generally leave clean holes.

The results of the auger bit testing were more interesting than their spade bit competitors. Auger bits are better for drilling through big timbers and built-up beams, as they pull through the material more easily than their spade bit counterparts. If your work makes it likely you’ll strike a nail on occasion, you’ll be pleased to know most bits came through my intentional strikes largely unscathed and were able to drill new holes after hitting a nail. Some auger bits made a clean entry but drilled slowly. Others drilled quickly, but left a messy hole, while one (the Milwaukee Speed Feed auger bit) couldn’t drill through the material at all due to the tip getting clogged.

Some of the 3⁄4-in. auger bit holes were tough to keep clean inside the lumber. The cutting edges on the bits really dig into the material, shearing the wood in larger chunks, but not pushing material out of the hole in the same way that a spade bit does.

Do clean holes really matter? I think it depends. For ledger bolts and other bolted connections, it probably doesn’t matter, but I think a strong argument can be made that a cleaner hole will make it easier to run wires and piping through them. Additionally, a clean hole means less likelihood of damaging a cable as it’s pulled. One thing that surprised me is that the 3⁄4-in. spade bits had a tough time striking through the embedded nail. On the other hand, the 1⁄2-in. bits were able to either go through or wiggle around the nail. So if you think you might hit a nail or screw, use a smaller-diameter bit if you can.

Jeremy Kassel (@kasselconstruction) owns Kassel Construction in Glenmont, N.Y. Photos by Rodney Diaz, except where noted.

For more photos and details, click the View PDF button below:

Sign up for eletters today and get the latest how-to from Fine Homebuilding, plus special offers.

Get home building tips, offers, and expert advice in your inbox

With a new panelized metal roof, charred wood siding, and updated windows, HVAC, and plumbing, this midcentury ranch remodel is starting to look like a modern home.

The designer and builder of the 2018 Fine Homebuilding House detail why they chose mineral-wool batts and high-density boards for all of their insulation needs.

"I have learned so much thanks to the searchable articles on the FHB website. I can confidently say that I expect to be a life-long subscriber." - M.K.

Get home building tips, offers, and expert advice in your inbox

Get home building tips, offers, and expert advice in your inbox

© 2024 The Taunton Press, Inc. All rights reserved.

Get home building tips, offers, and expert advice in your inbox

Become a member and get instant access to thousands of videos, how-tos, tool reviews, and design features.

Start your subscription today and save up to 70%

Get complete site access to expert advice, how-to videos, Code Check, and more, plus the print magazine.

Wood Carving Rotary Bits Already a member? Log in